This week’s episode is a continuation of last week’s conversation with Kim… not co-host Kim… but Kim from Kandal province in Cambodia.

She’s part of a growing group of university educated young South East Asians passionate about sustainability and working within the fashion industry. She started her career working for a major logistics company, which is what we covered in last week’s episode.

This week, we’re lucky enough to get to chat to Kim again, this time about her time working for a buying office as a Quality Production Leader. The brand for which Kim worked had an unusually close relationship with the factories producing their goods – which, we should note, were not owned by the brand. We look at the conditions that facilitated this quite transparent and close relationship – like the contract terms, the sharing of certain financial risks and even the technical nature of the products being produced.

But while we see quite a positive example of a relationship between brand and factory management on the one hand, we also hear about Kim’s struggle to mediate and improve the relationship between factory management and workers. We consider what strategies brands could take to be more effective in this space, and the complex relationship between purchasing terms, the pressure to reduce costs, and sustainability goals.

We learned so much from this conversation and are so excited to share it with you.

Photos Waldemar Brandt

Want to dig deeper ?

Want to learn more about how contract terms and purchasing practices shape the relationship between suppliers and brands?

Read co-host Kim’s piece about the urgency of addressing purchasing practices in Common Objective.

Or, read Better Buying’s recently released report on the minimally acceptable payment terms and standards.

Interested in learning more about Chinese owned and managed garment factories operating outside of China?

This article in the Chinese Daily gives a good overview.

But for more in-depth insight, check out this nuanced perspective on Chinese approaches to management published in Harvard Business Review. It’s a must-read for sustainability advocates seeking insight into how to engage with Chinese factory management.

And finally, if all this social distancing means your movie watch-list is getting low, we highly recommend the critically acclaimed Netflix documentary American Factory. Though not specific to the garment industry, this documentary offers rare and nuanced insight into a Chinese manufacturing company setting up shop in the United States.

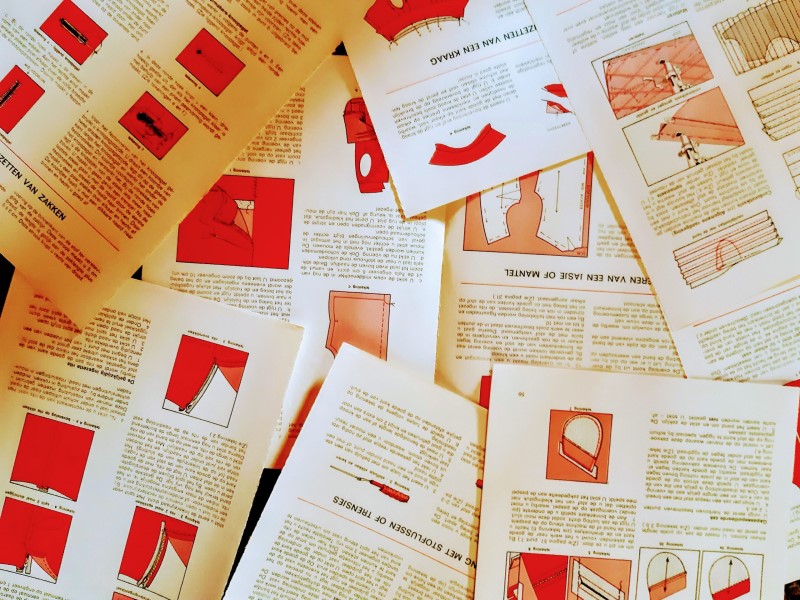

Photo Kim van der Weerd (left) / SinAbrochar (right)